Bekijk onze oplossingen

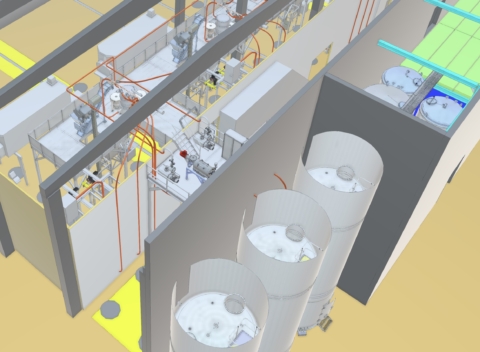

Opslag

De opslag van bulkgoederen gebeurt best optimaal zodat de kwaliteit van uw eindproduct gewaarborgd blijft. Uw silo’s of big bags beantwoorden dan ook aan de hoogste kwaliteitsnormen. Bewezen technologieën herleiden […]

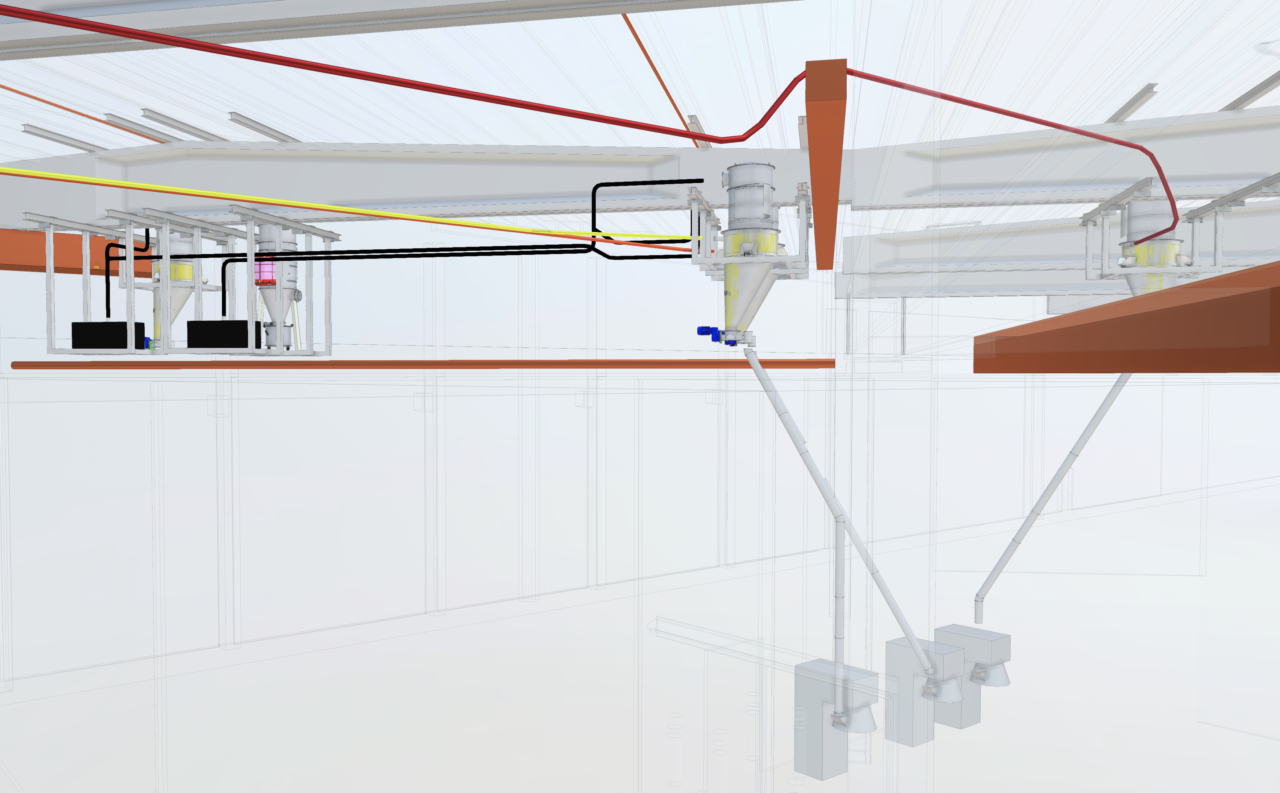

Transportsystemen

Uw grondstoffen transporteren vanuit de silo (of big bag) naar het volgende station? Dat gebeurt best op een hygiënische, efficiënte en eenvoudige manier. Ongeacht of het nu buiten of binnen […]

Wegen & Doseren

Voor een constante kwaliteit is het belangrijk om uw grondstoffen en hulpstoffen nauwkeurig te wegen en te doseren. Wij ontwierpen ons eigen weeg-, doseer- en mengsysteem. 3 in 1 voor […]

Zeven & Mengen

Soms neemt u liever geen enkel risico en streeft u naar 100% zuiverheid. Of u creëert in uw productieproces graag een nieuwe homogene stof na toevoeging van een nieuw bestanddeel. […]

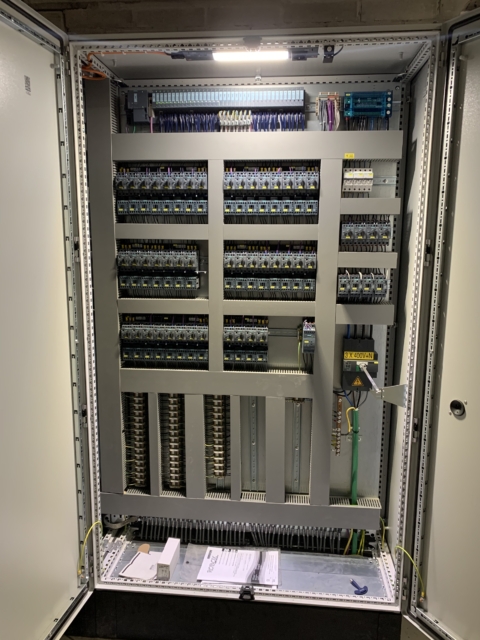

Automatisatie

Verdelen, wegen, mengen, filteren, transporteren, … Natuurlijk verwacht u een volautomatisch bulksysteem. Alle apparaten maken deel uit van een geïntegreerde installatie met een procescomputer. De bediening gebeurt via een monitor. […]

Ons stappenplan, van

idee tot eindresultaat

Start u met een nieuwe zaak, denkt u aan een uitbreiding of wilt u uw productieproces verbeteren? Doe een beroep op onze jarenlange expertise voor het uittekenen en installeren van uw geautomatiseerde totaaloplossing voor bulkbehandeling. Inclusief service en onderhoud.

Over ons

Wij installeren al meer dan 50 jaar totaaloplossingen voor de bulkbehandeling van poedervormige, korrelvormige en vloeibare producten hoofdzakelijk voor voedingsbedrijven, van kmo’s tot multinationals.

Onze focus?

Persoonlijke service en een optimale prijs-kwaliteitverhouding.

grondstoffen

grondstoffen